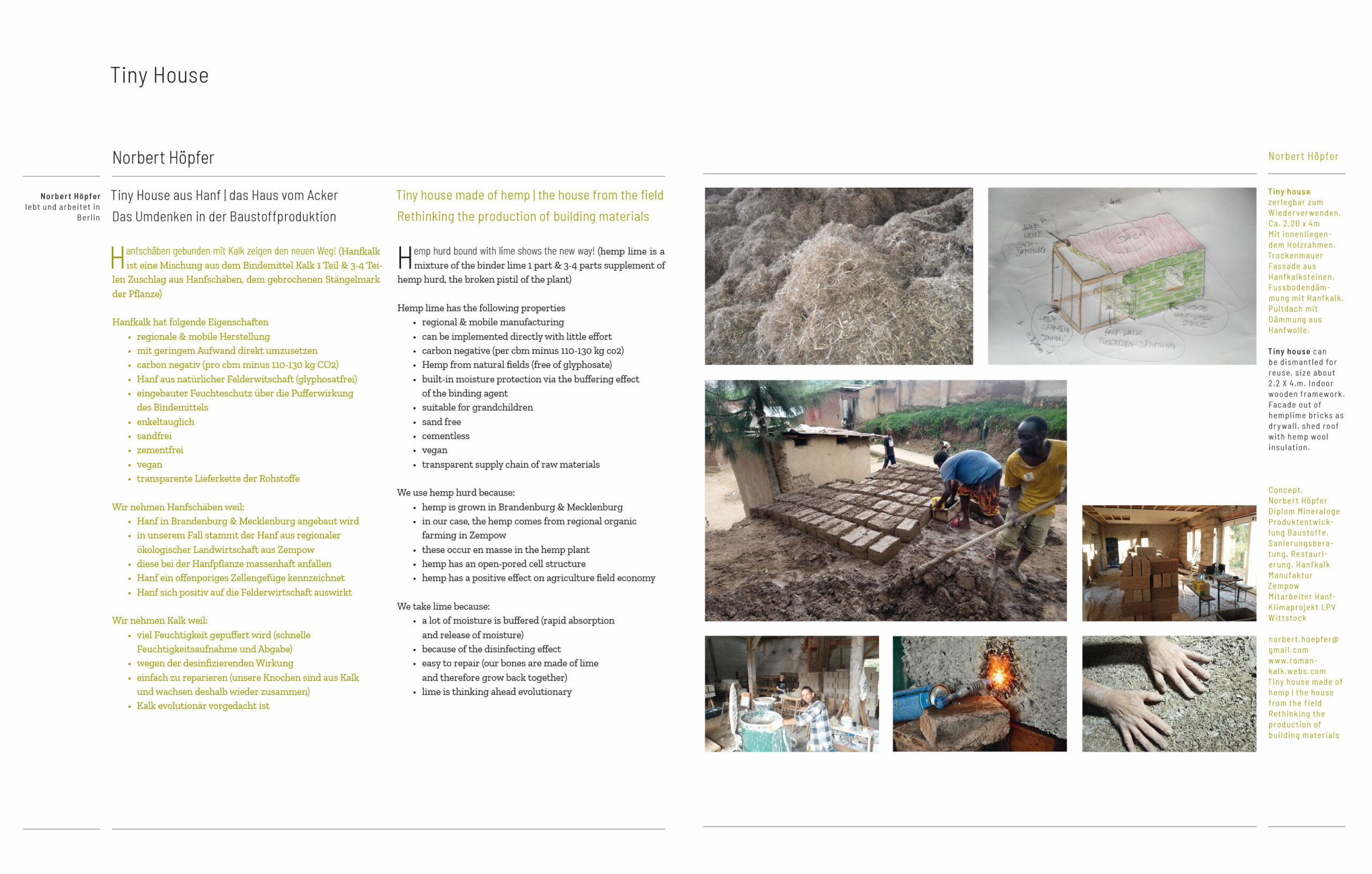

For sustainability, a coordinated production chain is required that is created in a single location, e.g. a factory: From the cultivation of this climate-friendly plant → harvesting technology → hemp processing, separation of the raw material into shives and fibers → production of the hemp-lime insulating blocks → their processing.

Industrial hemp has been cultivated in agriculture again since the 1990s. The plant, processed into an ecological, climate-positive building material, binds more CO2 during growth than is released during construction! (1 kg of hemp binds 1.5 kg of CO2, hemp lime is CO2 negative). Hemp has an open-pored cell structure. Additionally: Good ecological balance, as hemp requires little water and grows to maturity in around four months. The harvest from a 1-2 hectare field is enough for a small house.

A tiny house saves around a ton of CO₂! Hemp is used in e.g. B. grown in Brandenburg and Mecklenburg has a positive effect on glyphosate-free farming. Fibers from hemp stalks are used to make insulation materials, for example for roof areas. The shives are the basis for the hemp building blocks. Hemp lime can also be produced regionally and with little effort, has built-in moisture protection through the buffering effect of the binder, is suitable for grandchildren, is free of sand and cement, and is vegan

In contrast to conventional insulating blocks, hemp blocks do not create a build-up of moisture because hemp and lime balance moisture.

The hemp building blocks consist of hemp, lime (or clay) and water.